A smart BMS instantly protects your battery from over-discharge by using real-time monitoring and rapid cutoff. Over-discharge can damage battery cells, shorten lifespan, or cause safety issues. You need fast, automated protection to keep your battery healthy.

Battery AI predictions show real-time State of Health estimates with less than ±3% deviation from annual test results, proving accurate and reliable monitoring.

Modern battery systems use rapid cutoff to double or even triple battery life by disconnecting power when needed. Eight key mechanisms work together to provide this instant protection.

A smart BMS constantly monitors battery voltage, current, and temperature to spot problems early and protect your battery from damage.

Fast response features like rapid cutoff and electronic fuses stop over-discharge and overcurrent instantly, keeping your battery safe.

Cell balancing keeps all battery cells charged evenly, which extends battery life and prevents harmful deep discharge.

Advanced algorithms estimate how much charge remains and set safe discharge limits to avoid battery damage and surprises.

The smart BMS uses automated protection and self-checks to catch faults quickly and keep your battery reliable without extra effort.

You need to know what happens inside your battery at all times. A smart BMS acts like a watchdog, checking the voltage of every cell in real time. This constant tracking helps you spot problems before they get worse. High-frequency voltage sensors and microcontrollers work together to give you accurate readings. The system uses advanced algorithms and lookup tables to interpret what the voltage means for your battery’s health.

Voltage measurement alone does not tell you everything about your battery.

Smart battery systems combine voltage, current, and temperature data for better accuracy.

Full charge and discharge cycles help calibrate the system, fixing errors that can build up over time.

Proprietary algorithms and rapid-test methods, like Electrochemical Impedance Spectroscopy, improve state estimation.

Calibration and multi-parameter checks make sure the tracking stays reliable.

Tip: Regular calibration and multi-sensor monitoring keep your battery’s voltage tracking sharp and dependable.

Here is a table that shows how continuous voltage monitoring supports battery health and safety:

Performance Metric / Feature | Description / Validation Impact |

|---|---|

Voltage Measurement Accuracy | Resolution better than ±5mV ensures precise SOC and SOH estimation, critical for battery health and charge level |

Real-Time Monitoring | Enables immediate anomaly detection and quick system response to prevent over-voltage, under-voltage, and failures |

State of Charge (SOC) Estimation | Voltage data is a key indicator to estimate remaining battery energy |

State of Health (SOH) Analysis | Long-term voltage trends help assess battery aging and degradation |

Protection Mechanisms | Accurate voltage data allows prevention of over-voltage and under-voltage conditions |

Cell Balancing | Detects cell imbalances to trigger equalization, improving lifespan and efficiency |

System Architecture Components | High-frequency voltage sensors, ADCs, microcontrollers, and communication modules support reliable monitoring |

Data Logging and Predictive Analytics | Historical voltage data enables failure prediction, run-time estimation, and dynamic charge/discharge adjustments |

Scalability | Supports monitoring of multiple cells in series or parallel configurations for diverse applications |

Application Examples | Electric vehicles, industrial forklifts, renewable energy storage, medical equipment benefit from these features |

Challenges Addressed | Precision vs. cost, noise, temperature compensation, and calibration ensure measurement integrity |

You want your battery to last as long as possible. The smart BMS helps by instantly disconnecting the load if any cell drops below a safe voltage. This quick action stops over-discharge, which can damage your battery or even cause safety problems. The system responds in real time, so you do not have to worry about slow reactions or missed warnings.

When the smart BMS detects a cell reaching the undervoltage threshold, it acts right away. The system cuts off the power, protecting your battery from harm. This feature works in electric vehicles, renewable energy storage, and many other applications. You get peace of mind knowing your battery is safe and healthy.

You need to watch the current flowing through your battery. A smart BMS uses sensors to check the current every moment. This helps you spot problems before they damage your battery. If the current gets too high, the system can act fast to protect your battery and connected devices.

Machine learning algorithms, such as One Class Support Vector Machine (OCSVM), Isolation Forest, and Angle-Based Outlier Detection, run directly on sensor nodes. These methods help you find unusual current patterns quickly and with high accuracy.

The system collects data on current, voltage, temperature, and impedance. It looks for sudden changes in current that may signal a fault or battery wear.

Real-time alerts let you know if something is wrong, so you can take action before the battery gets damaged.

You can see how overcurrent detection works in the table below:

Threshold Current (A) | Duration (microseconds) | Spike Example (Current x Duration) | Detection Outcome | Notes |

|---|---|---|---|---|

400 | ≥ 2 | 500 A for 2 µs | Detected | Spike exceeds threshold and duration |

400 | ≥ 2 | 2000 A for 1 µs | Not Detected | Spike too short despite high current |

600 | ≥ 2 | 2000 A for 1 µs (multiple spikes) | Not Detected | Threshold too high to detect short spikes |

600 | ≥ 2 | 500 A for 2 µs (multiple spikes) | Not Detected | Threshold too high to detect these spikes |

Note: Some systems use extra methods that check past current, power loss, and temperature to improve protection.

You want your battery to stay safe, even during sudden faults. Traditional fuses and circuit breakers react too slowly to protect sensitive electronics. They may take thousands of times longer than needed. E-fuses, which are electronic fuses, solve this problem.

E-fuses can detect and stop dangerous overcurrent in just 1 to 10 microseconds. This speed keeps your battery and devices safe from short circuits.

E-fuses use semiconductor switches and current sensors. These parts work together to cut off power almost instantly.

Fast response means less risk of damage and longer battery life.

A smart BMS with fast current monitoring gives you peace of mind. You know your battery will react quickly to any problem, keeping your system safe and reliable.

You need to keep your battery safe from heat. A smart BMS uses temperature sensors to watch both the battery and the air around it. These sensors check the temperature all the time. If the battery gets too hot or too cold, the system can act fast to protect it.

Temperature sensors track battery and ambient temperatures inside the storage system.

Real-time data lets the system turn on cooling fans or open vents when needed.

Early detection of rising temperatures helps the system slow down charging or discharging to keep things safe.

The system stores temperature data. This helps engineers improve cooling designs and spot problems before they get worse.

Sensors can work with other safety tools, like gas or humidity sensors, for better protection.

You can trust these sensors because tests show they work well. For example, during a thermal runaway test, one battery module caught fire, but the three next to it stayed below 200 °C. This means the system stopped the fire from spreading. The battery pack also used special valves to release pressure and keep the box safe. Protective plates and materials kept flames and heat from damaging the battery cover. These features show that thermal protection works in real life.

You want your battery to work in hot summers and cold winters. A smart BMS can cut off charging or discharging if the temperature goes outside safe limits. This keeps your battery from getting damaged.

At very low temperatures, like -10 °C, the battery’s resistance goes up. The voltage drops faster, so the system cuts off power earlier to prevent harm.

Charging power drops by about 15% at -10 °C compared to normal room temperature.

Good thermal management, like preheating or cooling, helps the battery charge better and last longer.

At high temperatures, the system watches for signs of overheating. If needed, it stops charging or discharging to avoid damage.

Tests with electric vehicles show that these cutoff features work. The system uses voltage and temperature data to decide when to stop charging or discharging. This keeps your battery safe, even in extreme weather.

You need to know how much energy your battery has left. A smart BMS uses advanced algorithms to estimate the State of Charge (SOC) in real time. This helps you avoid surprises and plan your battery use better. The system collects data from voltage, current, and temperature sensors. It then runs calculations to predict the remaining charge.

Researchers have tested different methods to improve SOC accuracy. For example, a study used simple recurrent units with an unscented Kalman filter. This method achieved a root mean square error (RMSE) of less than 0.034 for one battery type and even lower for another, showing fast and accurate results. Another approach, the variable window adaptive extended Kalman filter, updates its calculations based on error changes. This method proved more accurate and robust than older models, even when starting conditions changed.

You can trust these results because experts use strict tests to check SOC accuracy. They use metrics like RMSE, Mean Absolute Error (MAE), and the coefficient of determination (R²). These numbers show how close the predictions are to real values. For example:

RMSE checks the average size of errors, especially big mistakes.

MAE looks at the average error size, no matter the direction.

R² tells you how well the model matches real data.

Performance tests use real driving cycles and hardware setups. One test compared SOC estimates from an Extended Kalman Filter to measured values during a Hybrid Pulse Power Characterisation test. The error was only about 4.2%, proving the method works in real life.

You want your battery to last longer and stay safe. The smart BMS sets a discharge limit to stop the battery from dropping too low. This limit is based on SOC calculations and real-world tests. Engineers run full charge-discharge cycles at fixed voltage limits, like 2.75 V to 4.2 V, and partial cycles within SOC ranges such as 20% to 80%. They measure capacity every 50 or 100 cycles to track battery health.

Tests also use dynamic stress profiles and different temperatures to check how the battery behaves. These benchmarks help set safe discharge limits and update SOC estimates. By following these tested limits, your battery avoids deep discharge, which can cause damage or shorten its life.

Tip: Trust the discharge limits set by your smart BMS. They come from real tests and proven data, keeping your battery safe and reliable.

You want every cell in your battery to work together. Cell balancing makes this possible. A smart BMS uses active balancing to move energy from cells with more charge to those with less. This process keeps the state of charge (SOC) even across all cells. When you have balanced cells, your battery works better and lasts longer.

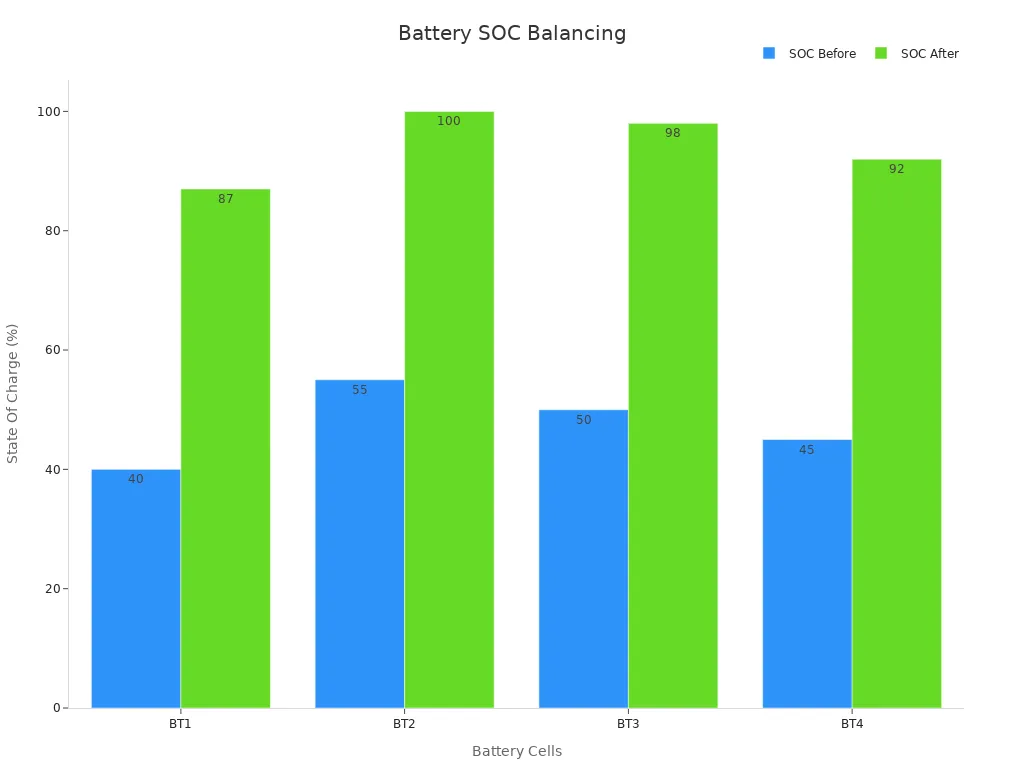

Here is a table that shows how active balancing improves SOC for each cell:

Battery Cell | SOC Before Active Balancing (%) | SOC After Active Balancing (%) | Improvement |

|---|---|---|---|

BT1 | 40 | 87 | +47 |

BT2 | 55 | 100 | +45 |

BT3 | 50 | 98 | +48 |

BT4 | 45 | 92 | +47 |

You can see the difference visually:

A smart BMS uses these balancing methods to help you in many ways:

Transfers extra charge from high SOC cells to low SOC cells.

Reduces uneven aging and cell wear.

Maximizes how much energy you can use from your battery.

Works faster by focusing on the biggest differences.

Keeps your battery safer by lowering heat and stress.

Extends battery life by keeping cells balanced.

You also benefit from high efficiency, low heat, and longer battery life. Some systems reach up to 96.5% efficiency during balancing.

You want to avoid deep discharge because it can damage your battery. Cell balancing helps by raising the SOC of weaker cells. This keeps every cell above the danger zone. When all cells stay balanced, your battery avoids stress and lasts longer.

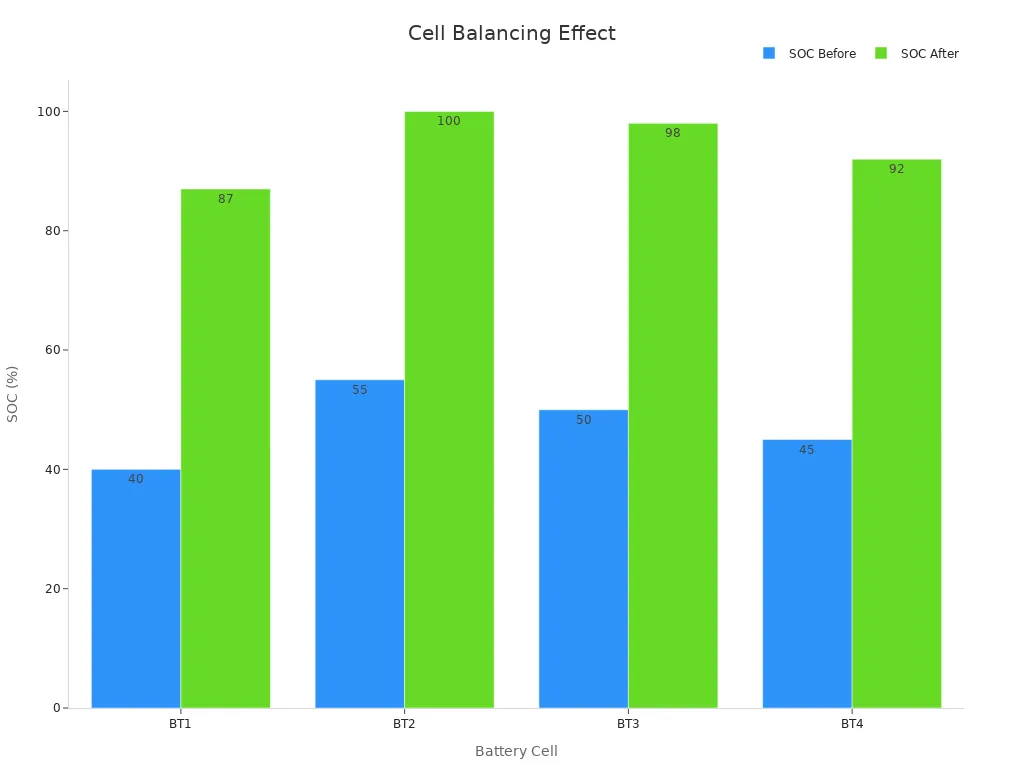

Here is another table that shows how balancing prevents deep discharge:

Battery Cell | SOC Before Balancing (%) | SOC After Balancing (%) |

|---|---|---|

BT1 | 40 | 87 |

BT2 | 55 | 100 |

BT3 | 50 | 98 |

BT4 | 45 | 92 |

Machine learning models show that balanced SOC data leads to better predictions of battery life. When you keep cells balanced, you get more accurate estimates of how long your battery will last. This helps you plan and use your battery safely.

Active balancing moves energy to weaker cells, reducing stress and heat.

Faster balancing means your battery stays healthy during every cycle.

Uniform SOC slows down cell aging and extends battery life.

Tip: Trust your smart BMS to keep cells balanced. This protection helps you avoid deep discharge and get the most from your battery.

You rely on discharge control circuitry to keep your battery safe. This system uses FETs (field-effect transistors) and contactors as safety switches. FETs work as solid-state switches. They turn on and off quickly to control the flow of electricity. Contactors are mechanical switches designed for high current. They open or close circuits to connect or disconnect your battery from the load.

FETs have low voltage drops and generate heat, so you often see several used in parallel for high-power batteries. They need heat sinks and extra safety features, like fuses, to prevent damage. Contactors handle large currents and use double contact gaps to stop dangerous arcs. Pre-charge resistors help reduce inrush current, which protects the contacts from welding together. Latching contactors save energy by holding their state without constant power.

Here is a table that shows key performance figures and efficiency factors for FETs and contactors:

Component | Performance Figures | Efficiency Considerations |

|---|---|---|

MOSFETs | Voltage drop with current, heat generation, parallel use for high current, needs fusing | Solid-state, low cost, limited current per device, needs cooling |

Contactors | Handles high current, risk of arcing, uses pre-charge resistors, latching design | High power, mechanical wear, needs infrequent switching |

Tip: You get the best protection when your smart BMS uses both FETs and contactors for different situations.

You need your battery to react fast when trouble happens. Discharge control circuitry can cut off power in just 100 to 200 milliseconds. This quick response protects your battery from damage caused by over-discharge or short circuits. Pure Ohmic resistance in the circuit causes an instant voltage drop, which helps the system detect problems and act within 0.1 seconds.

High-speed comparators and undervoltage detectors monitor the system and shut off switches in microseconds. Crisis power management features can switch power sources instantly to keep your devices running. These fast actions prevent overheating, fires, and permanent battery damage.

Here is a table showing design benchmarks and response times for discharge control circuitry:

Feature / Benchmark | Description / Performance Data |

|---|---|

Ideal Diode Circuit | Tracks voltage with 30x less power loss than Schottky diodes |

High-Speed Comparators | Shut off MOSFETs within microseconds |

Undervoltage Detector | Activates all power sources within 10 microseconds |

Crisis Power Management | Switches power sources instantly to maintain load power |

Short-Circuit Protection | Protects MOSFETs from damage using time and current-based systems |

You can trust that your smart BMS will act quickly to keep your battery safe and extend its life.

You want your battery system to spot problems before they cause harm. A smart BMS uses advanced error detection to watch for faults in real time. This system checks for unusual voltage, current, or temperature patterns. It uses both hardware sensors and smart algorithms to find issues early.

Modern error detection methods use cloud computing and machine learning. These tools help you catch faults that older systems might miss. For example, new models can track battery voltage during charging and discharging with over 99% accuracy. The system learns from real-world data, so it can adjust to changes in driving or weather. This means you get fewer false alarms and more reliable protection.

Here is a table that shows how well these methods work compared to older models:

Aspect | Proposed Method | Transformer Model | LSTM Model | BPNN Model |

|---|---|---|---|---|

Accuracy during Charging (%) | 99.803 | 98.245 | 95.450 | 92.208 |

Accuracy during Discharging (%) | 99.507 | 97.864 | 93.472 | 91.662 |

Note: The smart BMS uses adaptive thresholds, so it can spot faults even when conditions change. This keeps your battery safe in many situations.

You need fast action when a fault appears. The smart BMS does not wait. It reacts right away to protect your battery and devices. When the system finds a problem, it can disconnect the battery, send an alert, or switch to a backup mode.

You benefit from high diagnostic accuracy. One optimized system reduced misdiagnosis rates by 81.9%. Another method reached a 92.1% success rate in finding faults. These numbers show that you can trust the system to act quickly and correctly.

The smart BMS checks for errors many times each second.

It uses both local and cloud-based tools for better results.

You get real-time alerts, so you can fix problems before they get worse.