The top 10 BMS suppliers for lithium-ion batteries in 2025 are KURUI BMS, CATL, Ewert Energy Systems, STAFL Systems, Nuvation Energy, AYAA Technology, DALY BMS, TRITEK LEV, Lithium Balance, and Panasonic. Each company is a leader because of new ideas, trust, advanced technology, or a big part of the market. The table below shows how fast the lithium-ion battery sector is growing. Suppliers like CATL and SINO WEALTH have reached big goals in making batteries and earning money.

Metric | Value | Notes |

|---|---|---|

Global production capacity | Baseline (2022) | |

Expected CAGR (2022-2026) | 33% | Market growth rate |

CATL production (2022) | 96.7 GWh | Leading supplier |

SINO WEALTH Q3 2024 revenue | Strong financial growth |

Picking the right BMS supplier keeps lithium-ion battery systems safe, efficient, and long-lasting. This helps the market grow fast and gives better ways to use batteries.

Battery Management Systems help lithium-ion batteries stay safe and work well. They watch the voltage, current, and temperature all the time.

Leading BMS suppliers like KURUI, CATL, and Panasonic use new technology. They have good safety features and are known around the world.

Smart BMS use AI and IoT to find problems early. They help batteries last longer and charge faster. They also make batteries work better.

Picking the best BMS supplier means looking at their technology and support. You should also think about how much it costs and if you can change it to fit your needs. This helps you in the long run.

The BMS market is growing quickly because of electric vehicles and green energy. Smart and safe battery management is now more important than ever.

A Battery Management System (BMS) works like the brain for a lithium-ion battery pack. It watches over each cell to keep the battery safe and working well. The BMS checks things like voltage, current, and temperature. It keeps every cell inside safe limits. If a cell gets too hot or cold, the BMS can turn on heating or cooling. This keeps the battery at a good temperature.

The BMS also makes sure all cells have a balanced charge. This is called cell balancing. It helps every cell work together and stops weak cells from causing trouble. Different uses need different BMS features. For example:

Electric vehicles need a BMS that can handle high charging and discharging. It must estimate state of charge (SOC) and state of health (SOH). It also does active cell balancing.

Stationary energy storage systems care about cycle life and saving money. They often use passive balancing.

Industry standards help guide how a BMS is made. Important standards are ISO 26262 for car safety and IEC 62660 for electric vehicle batteries. These rules say the BMS must watch battery health, estimate SOC, and protect the battery.

Note: A BMS must act fast when voltage, current, or temperature changes. Quick action stops damage and keeps the battery safe.

A BMS is very important for battery safety and performance. It stops dangerous things like overcharging, deep discharging, and overheating. Without a BMS, lithium-ion batteries are more likely to fail. They could even have thermal runaway, which can cause fires or explosions.

The BMS checks and controls voltage, current, and temperature to stop danger.

Problems in making the battery or using it wrong can cause short circuits. The BMS finds and fixes these before they get worse.

In high-energy uses like planes, BMSs stop failures from spreading between cells. This lowers the chance of big accidents.

Cell balancing keeps all cells at close voltage levels. This helps the battery last longer and work better.

System-level tests and checks, using BMS data, help engineers make batteries safer and work better.

A good BMS makes sure lithium-ion batteries give steady power. It also keeps people and equipment safe from harm.

KURUI BMS is known for strong safety and flexible design. Their battery management systems work with many lithium-ion chemistries. KURUI uses real-time monitoring and adaptive balancing to keep batteries safe. Their BMS works in electric vehicles, energy storage, and factories. KURUI focuses on research and development. This helps them make reliable and new products that meet tough industry rules.

CATL is a top company for lithium-ion batteries and battery management systems. Their BMS helps batteries last longer and stay safe. CATL made cobalt-free lithium iron phosphate batteries. These batteries are safer and better for the environment. Their fast-charging batteries reach 80% charge in 10 minutes. CATL’s Tener energy storage system uses new materials to stop capacity loss for five years. They also made a second-generation sodium-ion battery with high energy density. CATL works with big car companies and has more than 13 factories around the world.

CATL at a Glance:

Evidence Category | Details |

|---|---|

Market Share | Made 96.7 GWh out of 296.8 GWh worldwide in 2024, up 167.5% from last year. |

Technological Advancements | Advanced BMS, cobalt-free LFP, Tener energy storage, fast-charging, sodium-ion batteries. |

Global Presence | 13+ factories, works with car companies, batteries in cars and trucks everywhere. |

Sustainability Focus | Clean energy, battery recycling, lowest cost per kWh, $140B+ market cap. |

Ewert Energy Systems is known for new ideas in battery management systems. They make smart software for maintenance and modular hardware. Ewert’s BMS uses AI and cloud platforms to help batteries work better. The company works with partners to make new products faster. Ewert’s focus on modular design and teamwork helps them stay ahead.

Ewert Energy Systems is a top bms supplier because:

They lead in AI battery diagnostics.

They use modular hardware and cloud software.

They have partnerships for faster new ideas.

STAFL Systems makes high-performance BMS for electric vehicles and energy storage. Their products have strong hardware and smart algorithms for cell monitoring. STAFL’s BMS supports active balancing and real-time data logging. This helps batteries last longer. Their systems are reliable and easy to use in custom battery packs. STAFL works with car and industrial clients who need dependable battery management.

Nuvation Energy has put over 1 GWh of battery management systems in use worldwide. Their BMS is used in utility grids, EV charging, solar storage, and reused batteries. Nuvation’s BMS works with many battery chemistries, including reused EV batteries. They use high-precision monitors and special algorithms for cell balancing and state of charge. Nuvation’s systems meet UL 1973 safety rules and are made to last a long time. The company works with Analog Devices to improve technology and reach more markets.

Aspect | Summary |

|---|---|

Market Deployment | Over 1 GWh BMS used, hundreds of sites worldwide. |

Application Scope | Utility grids, EV charging, solar storage, reused batteries. |

Technology Innovation | Configurable BMS, high-precision monitoring, continuous cell balancing. |

Reliability & Safety | UL 1973 certified, long-term reliability, strategic partnerships. |

AYAA Technology makes high-performance BMS for homes, businesses, and factories. Their products have smart thermal management, overcurrent protection, and advanced cell balancing. AYAA uses AI and IoT for smart monitoring and early problem detection. Their BMS designs are eco-friendly and can be recycled. AYAA’s systems meet international safety rules like UL and IEC. Studies show their BMS can make batteries last 20% longer and cut maintenance costs by 15%.

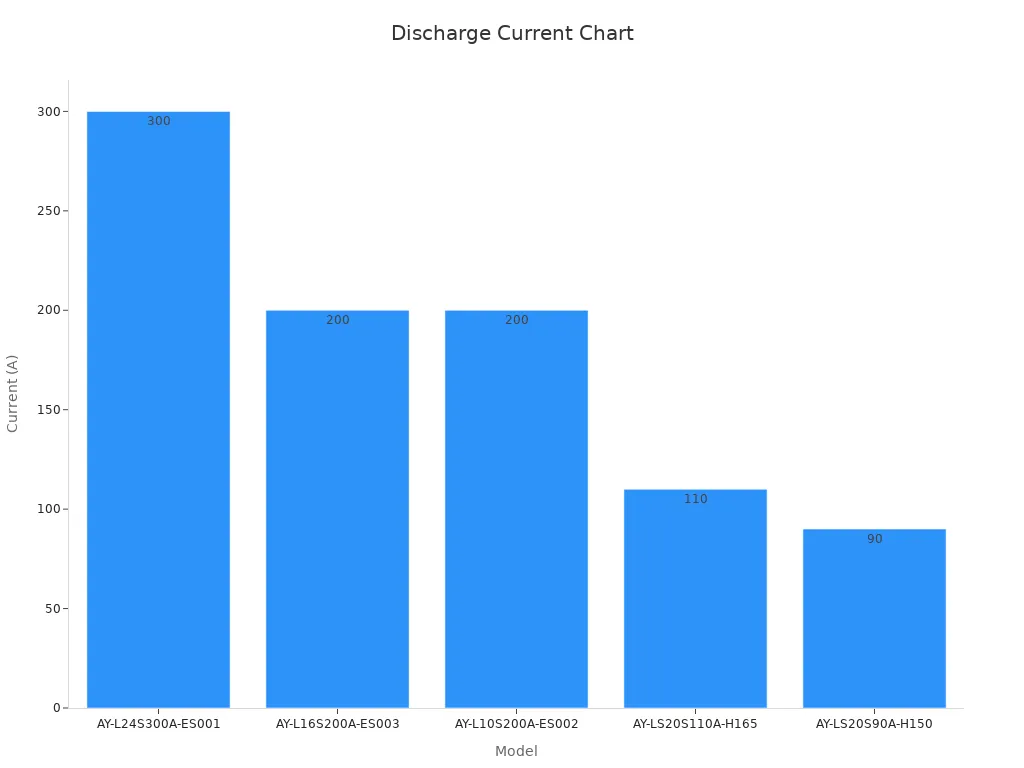

Model | Series | Continuous Discharge Current | Key Features and Benefits | Warranty | |

|---|---|---|---|---|---|

AY-L24S300A-ES001 | 7S-24S | Up to 300A | Home, Business, Factory | Thermal runaway protection, smart thermal management, longer battery life | 5 years |

AY-L16S200A-ES003 | 8S-16S | 200A | Scalable grid systems | Overcurrent protection, scalable design | 4 years |

AY-L10S200A-ES002 | 3S-10S | 200A | Mobile, remote storage | Cell balancing, data logging | 3 years |

AY-LS20S110A-H165 | 16S-20S | 110A | Industrial high-load | Smart thermal management, ageing compensation algorithms | 5 years |

AY-LS20S90A-H150 | 16S-20S | 90A | Cost-sensitive projects | High integration, overcharge protection | 3 years |

DALY BMS is known for safety, reliability, and smart diagnostics. They use sensors and converters to get accurate data. DALY’s BMS has backup hardware and smart fault detection using machine learning and AI. Their systems use built-in algorithms for state of charge, health, and cell equalization. DALY’s BMS supports IoT and cloud computing for digital twins and better control. After 300 cycles, their systems keep 88% capacity in NMC cells, showing strong reliability.

Aspect | Summary |

|---|---|

Data Acquisition & Sensors | Voltage, current, temperature sensors, backup hardware. |

Fault Detection Methods | Adaptive EKF, machine learning, AI for quick diagnosis. |

Control Strategies | Built-in algorithms, IoT, cloud computing, digital twins. |

Reliability Statistics | 88% capacity left after 300 cycles for 3000 mAh NMC cells. |

Overall BMS Role | Keeps batteries safe, checks for problems, protects, and improves efficiency. |

TRITEK LEV makes battery management systems for light electric vehicles like e-bikes and scooters. They have over 15 years of experience in research and custom battery design. TRITEK’s BMS offers smart integration, quality, and reliability. The company works with top brands in the LEV and electric drive markets. TRITEK’s knowledge in BMS design helps them meet today’s and tomorrow’s electric vehicle needs.

TRITEK LEV’s main strengths:

Smart BMS for LEVs.

Over 15 years of experience.

Works with top LEV and electric drive brands.

Focus on quality, reliability, and new ideas.

Lithium Balance is one of the biggest BMS makers in the world. They offer modular BMS for high-performance and scalable uses. Lithium Balance keeps its place by investing in research and partnerships. Their systems fit many battery sizes and help electric vehicles, green energy, and electronics work better. Lithium Balance is strong in the U.S., Asia-Pacific, and Europe, helping green energy and battery technology grow.

Metric/Aspect | Details |

|---|---|

Market Position | One of the largest global BMS makers. |

Innovation Focus | Modular, scalable BMS for many uses. |

Market Growth | |

Regional Insights | Strong in U.S., Asia-Pacific, Europe; driven by EV and green energy demand. |

Competitive Strategies | Always innovating, partnerships, investing in making products. |

Panasonic is a top supplier of battery management systems for electric vehicles and energy storage. They use IoT and cloud AI to predict battery life and check performance. Panasonic’s BMS helps the transportation sector, which is the biggest market. The company builds new factories, like the Kansas plant, to make more batteries in North America. Panasonic’s plan includes mergers, partnerships, and new products to stay ahead in the fast-growing market.

Aspect | Details |

|---|---|

Market Size (2025) | $16.00 Billion |

Projected Market Size (2030) | $34.79 Billion |

CAGR (2026-2032) | 16.27% |

Technology Trends | IoT, AI, edge computing, built-in analytics. |

Strategic Moves | New factories, partnerships, new products, vertical integration. |

Regional Influences | Asia-Pacific incentives, European rules, North American growth. |

Picking these bms suppliers gives you the newest technology, safety, and expert help for lithium-ion battery projects.

The table below shows the main features of top BMS suppliers. It also lists their market focus and what makes each one special.

Supplier | Main Features | Market Focus | Unique Points |

|---|---|---|---|

KURUI BMS | Real-time monitoring, adaptive balancing | EVs, energy storage, industry | Flexible design, strong R&D |

CATL | Advanced BMS, fast charging, LFP tech | Automotive, grid storage | Global scale, cobalt-free batteries |

Ewert Energy | Modular hardware, AI diagnostics | Custom projects, R&D | Cloud-based analytics, rapid innovation |

STAFL Systems | Active balancing, data logging | EVs, industrial | High reliability, custom integration |

Nuvation Energy | High-precision, UL certified | Utility, solar, reuse | Configurable BMS, long-term reliability |

AYAA Technology | AI, IoT, eco-friendly design | Home, business, factory | Smart monitoring, recyclable systems |

DALY BMS | Smart diagnostics, IoT, ML algorithms | EVs, consumer electronics | Digital twins, strong reliability |

TRITEK LEV | Smart BMS, custom design | Light electric vehicles | 15+ years experience, LEV focus |

Lithium Balance | Modular, scalable, global reach | EVs, green energy, electronics | Partnerships, innovation investment |

Panasonic | IoT, AI, edge analytics | EVs, energy storage | Vertical integration, global expansion |

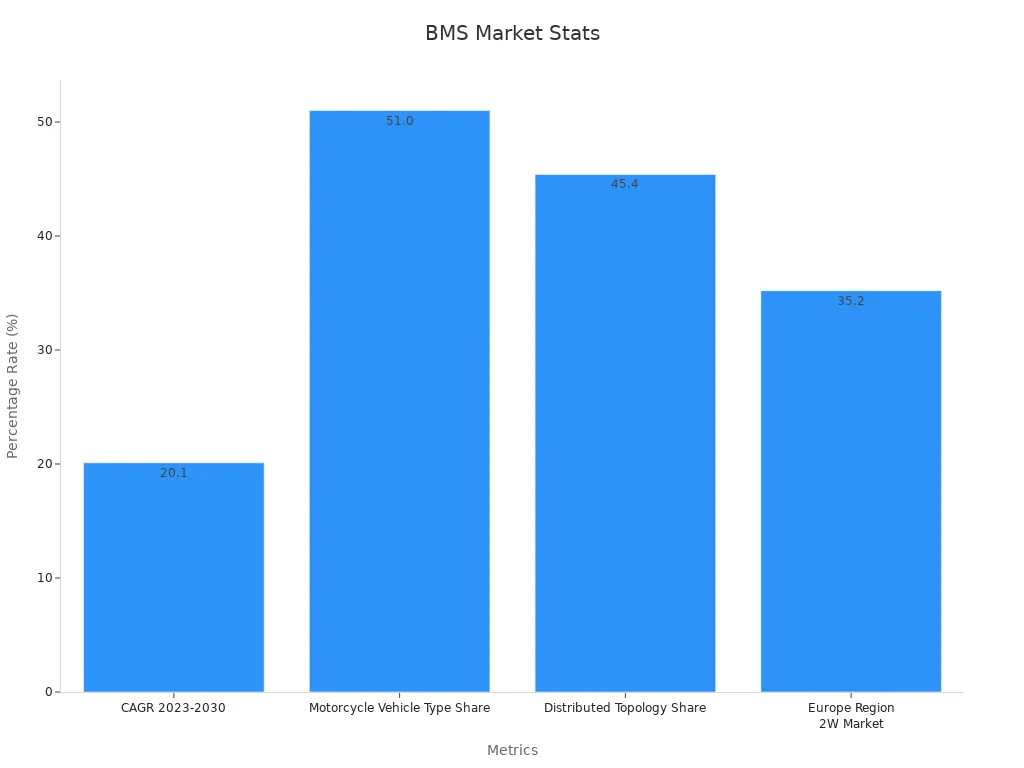

BMS suppliers work in different places and for different uses. In 2022, the global BMS market was worth $0.53 billion. It is expected to grow by 20.1% each year until 2030. Electric two-wheelers make up 51% of the market. Europe leads this part with 35.2%. Distributed topology is 45.4% of the market. North America will be the leader from 2025 to 2032. This is because more people are buying electric vehicles and there are government rewards. Asia-Pacific will grow fast too. This is due to strong factories and good EV rules. Companies like Panasonic, Leclanché, and Elithion have strong plans for their regions.

The car industry is growing fastest for lithium-ion BMS. Wired BMS is used the most, but wireless BMS is getting more popular. Government help and more EVs in China, Europe, and North America support this growth.

Each supplier has something special to offer:

KURUI BMS gives flexible options for many battery types.

CATL is a leader in fast-charging and green battery tech.

Ewert Energy uses AI and cloud tools for smart checks.

STAFL Systems is known for being reliable and custom-made.

Nuvation Energy is trusted for long life and UL safety.

AYAA Technology makes BMS that are green and can be recycled.

DALY BMS uses digital twins and machine learning for safety.

TRITEK LEV focuses on light electric vehicles and has lots of experience.

Lithium Balance works with partners and builds new ideas.

Panasonic uses IoT and AI for smart checks and has a big reach.

These differences help customers pick the best partner. They can choose based on tech, custom needs, support, or price.

Picking a BMS supplier starts with looking at their technology. Top companies use smart sensors and microcontrollers. They also use ways to connect like CAN, Bluetooth, and IoT. These tools help keep batteries safe and stop thermal runaway. Many suppliers now use AI to check battery health and help with charging. New ideas include solid-state batteries and very fast charging. Some even use 3D-printed parts. These changes help batteries last longer and charge quicker. Suppliers also care about recycling and saving resources. They use smart ways to get back materials. Safety is important too. Features like thermal management, fault isolation, and auto shutdown keep people and equipment safe.

Sensors check voltage, temperature, and current in detail.

AI helps find problems and fix them before they get worse.

Good communication and cybersecurity keep data safe.

BMS can work in cars, energy storage, and factories.

Tip: Pick suppliers who use new ways to make and manage batteries.

Every battery job is different. The best BMS suppliers let you change things like chemistry, voltage, and size. They also help with fast charging and special safety needs. They follow rules like ISO 26262 and UL 2580 to make sure products are safe. Making a BMS includes planning, designing, building, testing, and helping after you buy.

Aspect | Description |

|---|---|

Customization Capabilities | Can change for chemistry, voltage, size, safety, and how it is used |

Industry Standards | ISO 26262, UL 2580, IEC 62619, IEC 62133, UN 38.3 |

Development Process | Plan, design, test, build, and support |

Customer Benefits | Safer batteries, longer use, save money, and follow rules |

Good support is very important. Top suppliers help with setup, fixing, and tech questions. Customers say they get answers fast and clearly. Service teams help with changes and special requests. Many people like that help continues as long as the battery is used. Being professional and caring makes customers happy.

Help after buying and when changes are needed

Teams listen and help with new needs

Support keeps going for the battery’s life

Note: Good support keeps batteries safe and working well for a long time.

Cost is important when picking a supplier. The best choice is not always the cheapest. You should look at price, technology, custom options, and support. Suppliers who use new ideas may cost more, but their systems last longer and save money later. Custom features and good help can lower repair and downtime costs. Buyers should look at the total cost, not just the first price.

Smart battery management systems are changing how batteries work. Companies use AI and IoT to watch batteries all the time. These systems can find problems before they happen. They also help fix things faster. Smart BMS can connect to the cloud. This lets people check battery health from anywhere. New battery chemistries like lithium iron phosphate and nickel manganese cobalt make batteries safer. They also help batteries last longer. Big factories called gigafactories make more batteries for less money. Recycling programs help keep batteries good for the planet. Many industries now use smart BMS. These include medical devices, planes, and smart homes.

New chemistries make batteries safer and last longer.

Gigafactories make more batteries and lower costs.

Recycling helps the planet.

More industries use smart BMS for new things.

Technology brings faster charging and better battery life.

Better BMS makes lithium-ion batteries much safer. Engineers test batteries to see how well BMS protects them. They use special tests to see how batteries handle stress and heat. New ways, like using lasers, help batteries hold more power and last longer. BMS now checks voltage, current, and temperature all the time. They stop batteries from getting too full, too empty, or too hot. Some batteries use special materials to soak up heat and protect them if they get hit. These changes make fires less likely and keep people safe.

Watching batteries in real time and using smart controls helps BMS keep batteries safe and working well.

The battery management system market is growing fast. In 2023, the global BMS market was $7.19 billion. Experts think it will reach $31.27 billion by 2030. This means it will grow by 23.4% each year. North America is the biggest market, but Asia-Pacific is growing quickly. This is because they make lots of electric vehicles and get help from the government. Lithium-ion batteries are growing the fastest. More electric cars, green energy, and new safety rules help this growth. Companies like CATL, LG Innotek, and Tesla lead with new tech and better prices. The market now has more wireless tools, AI, and smart ways to check battery health.

Metric | Value |

|---|---|

Global BMS Market Size in 2023 | USD 7.19 billion |

Projected Market Size by 2030 | USD 31.27 billion |

CAGR (2024-2030) | 23.4% |

Largest Regional Market in 2023 | North America |

Fastest Growing Battery Type Segment | Lithium-Ion Based |

The future for BMS is bright. Smarter and safer systems will power the next group of lithium-ion batteries.

Picking trusted and smart bms suppliers helps shape battery projects. The top 10 companies, like KURUI BMS, use new technology and work with strong partners. Experts say the market will grow fast and needs good partners:

Metric | Value/Description |

|---|---|

USD 10.2 billion | |

Projected Market Size (2035) | USD 23.2 billion |

Lithium-ion Battery Share (2025) | 44% of BMS market; over 80% of energy storage uses lithium-ion |

Key BMS Capabilities | Cell monitoring, balancing, AI-driven diagnostics |

Lithium-ion batteries make people want better BMS.

AI and cloud tools help keep batteries safe and last longer.

Working together and research help the industry move forward.

Picking the right BMS partner now keeps batteries safe, working well, and ready for new ideas in the future.

A BMS watches battery voltage, current, and temperature. It keeps each cell safe and balanced. This helps batteries last longer and work better.

Buyers should look at technology, safety, support, and cost. They need to see if the supplier offers custom options. It is important that the supplier meets industry standards. Good support and strong performance are most important.

Lithium-ion batteries can get too hot or break without a BMS. The system stops overcharging, deep discharging, and short circuits. It keeps people and equipment safe.

Most new BMS products work with many lithium-ion chemistries. Some systems also work with other battery types like lead-acid or sodium-ion. Always check the supplier’s details.